Research and Projects

Physical Twin

A fundamental question within manufacturing is how material properties such as strength can be predicted given a process. Ideally, every manufactured part would carry with it an array outlining relevant properties (corrosion, strength, thermal, etc.) as a function of location. Within other engineering disciplines such as fluid system design, mechanical design, or electrical system design, modeling can be used to predict how a given configuration will behave. However, predicting properties based on a given manufacturing process is currently computationally prohibitive due to the necessity to simulate complex thermal dynamics combined with solidification to predict the location of moles of atoms. For this reason, qualification of an alloy for a given manufacturing process is predominantly test-based and can last from years to decades.

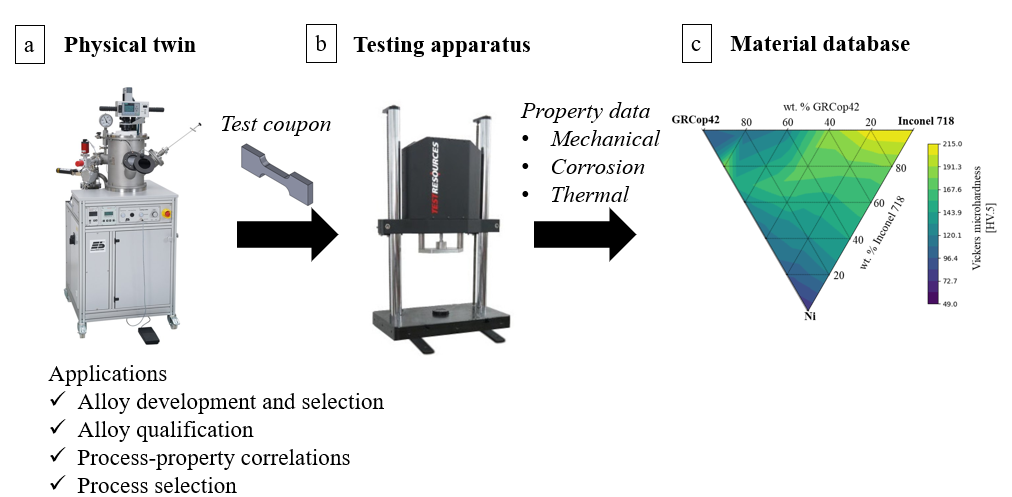

Current advances in machine learning (ML) have enabled the ability to correlate inputs and outputs from existing data resulting in the prediction of new information based on past knowledge (i.e. reasoning), and could be used to correlate processing conditions to properties. However, such ML approaches are only applicable if large, reliable datasets are available. Fabricating such datasets requires extensive effort due to the difficulty of both fabrication and testing. For example, researchers at Oak Ridge National Laboratory tested 6,299 stainless steel coupons fabricated via laser powder bed fusion to understand the impact of print orientation and parameters on mechanical properties; creating this dataset required a multi-month effort with multiple full-time engineers [1]. Thus, constructing a system optimized for mimicking a given additive manufacturing process to quickly fabricate test coupons and automate testing has the potential to rapidly generate a database of relevant material properties for downstream ML analysis. Such a system is dubbed as a “physical twin” (in contrast to a “digital twin” which is a simplified digital model).

[1] S. Luke, J. Chase, C. David, H. William, D. Ryan, P. Vincent, A Co-Registered In-Situ and Ex-Situ Tensile Properties Dataset from a Laser Powder Bed Fusion Additive Manufacturing Process, OLCF database (2023)

A New Format for Academic Journals

Academic publishing has not fundamentally changed in the past century despite changes in technology and the culture of academia. Specifically, when publishing in academic journals review times are known to take months, and reviews can be low quality. In addition, research output is measured by amount of publications and citation count, which does not necessarily correlate with high quality research. The goal of this project is to build a new framework for academic publishing which eliminates the inefficiencies of publishing (i.e. long review time) and promotes scientific discussion. Some features of the proposed platform include:

- Platform can take a manuscript in any file type (.docx, LaTex, .pdf) and subjects it to automatic formatting.

- Since most researchers read papers online, native support for interactive figures / animations are encouraged.

- Reviews are made public.

- Published papers have a comment section, where academic discussions can continue.

PhD Research: Joining Inconel and GRCop42

My PhD research focused on developing method a to join Inconel alloys (Ni-based alloy with high strength at high temperatures) to GRCop42 (Cu-based alloy with high thermal conductivity). One application which requires such joints is rocket exhaust chambers. My PhD research indicated these joints are prone to cracking when joining using liquid state processes due to a liquid miscibility gap (lack of liquid state mixing) which arises when the GRCop42 and Inconel mix within a melt pool. I subsequently developed two “transition compositions” which can be deposited in between GRCop42 and Inconel and allow for cracking to be avoided. The slides from my dissertation can be downloaded here.